In June, Ntico Logistics signed on to execute two Proofs of Concept (POCs) with a French logistics provider that has an international presence.

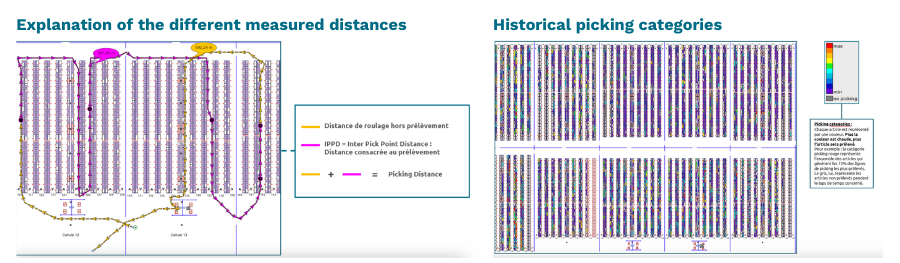

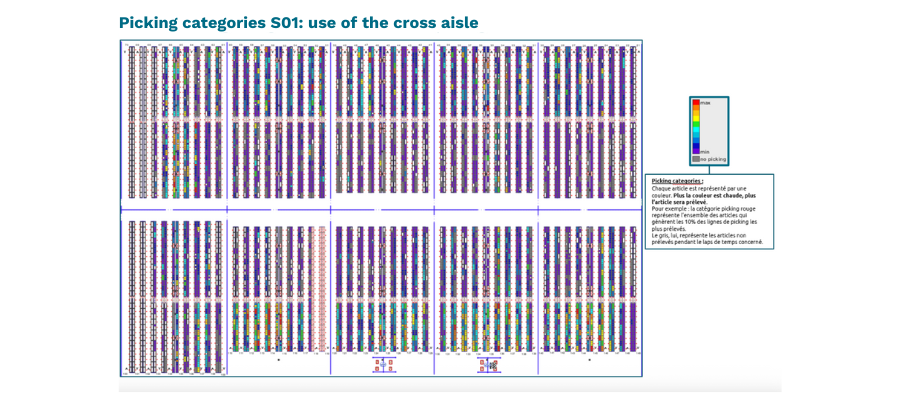

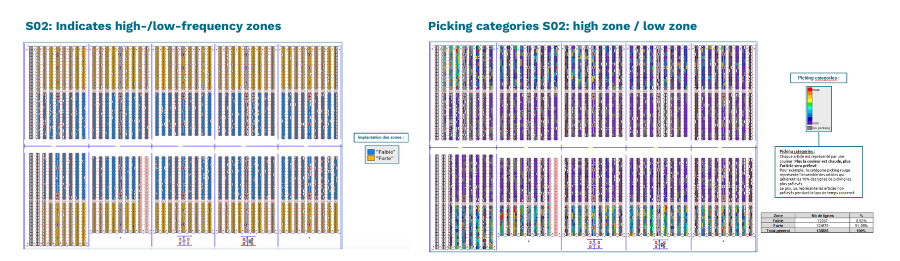

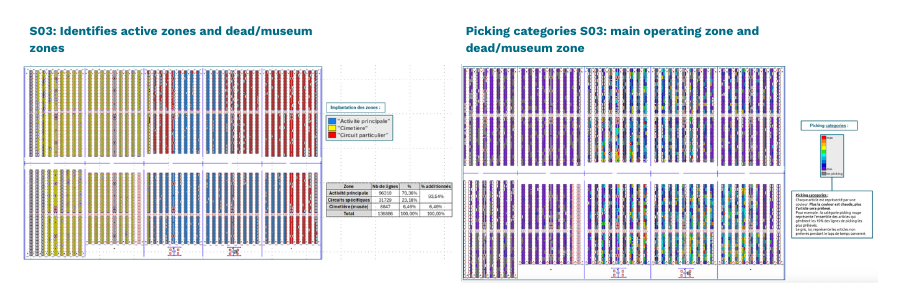

The objective ? Simultaneously audit two food related (Brewery / Alcohol / Grocery) warehouses and demonstrate the full capabilities of our optimisation tool PIkxtr@. Although their primary activity is similar, the two sites differ in many aspects (constraints, SKU, type of preparation, kind of final retailer…) Our teams are already mobilised on the ground to ensure an efficient handling of operations at both locations

This collaboration is not solely about demonstrating the capabilities of PIkxtr@; it’s intended to be the springboard for a deeper partnership between our two entities.

It will also allow our customer to manage their maintenance itself through the development of a special PIkxtr@ version, focused on end-user utilisation.

This partnership marks a new stage in our development, and we are eager to share the next advances with you.

Stay connected to follow the progress of this project !

Article written by :