From 14th to 16th of May 2025, our team went to Saint-Martin-de-Crau (FR – 13) to audit a warehouse of more than 1 000 000 sq ft dedicated to Furniture.

This audit in numbers

⏱️ 2 days on site

📦 58 1251,16 sq ft audited for the first step

🗂️ 6 000 SKU

👷 50 pickers

🔎 3 optimisations scenarios performed

Results obtained (Average over 3 scenarios)

✅ 21% gains in total distance

✅ 27% gains in picking distance

✅ 6,55% gains on stops

✅ 11% gains on replenishments

Challenged identified

The site was looking for a simple and quickly deployable solution in order to improve its productivity.

We therefore worked based on the existing structure while respecting every constraint :

Implementation circuits.

Defined sequencing,

Imposed splits and cuts,

Respect of dimensions constraints (paletts / slot for width and depth).

Proposed solutions

The restitution was held on the 17th of July 2025, only 6 weeks after the audit.

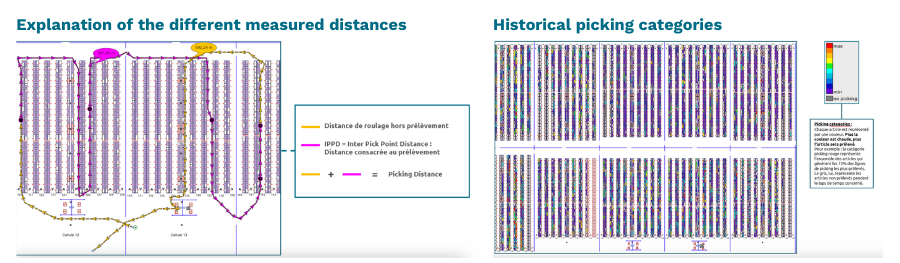

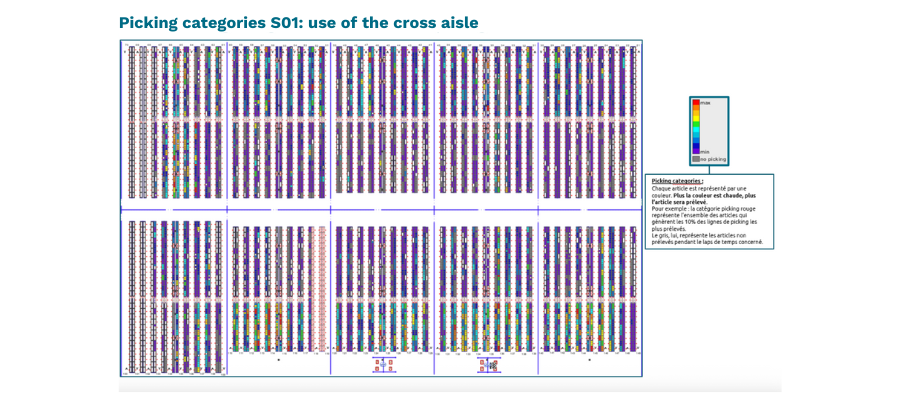

Scenario 1 : Implementation optimisation by our optimisation engine, PIKXTRA, without changing the existing structure.

→ 8 sub-scenarios proposed, including moving one circuit and the reuse of a locked cross aisle.

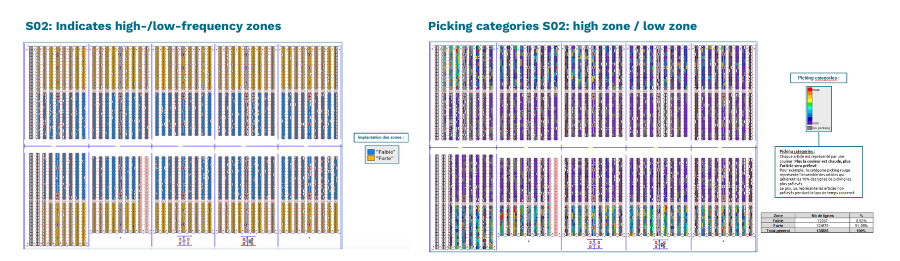

Scenario 2 : Based on scenario 1, adding High and Low frequency zones

→ High-picked items are set closer to ending docks to reduce full aisle traversals.

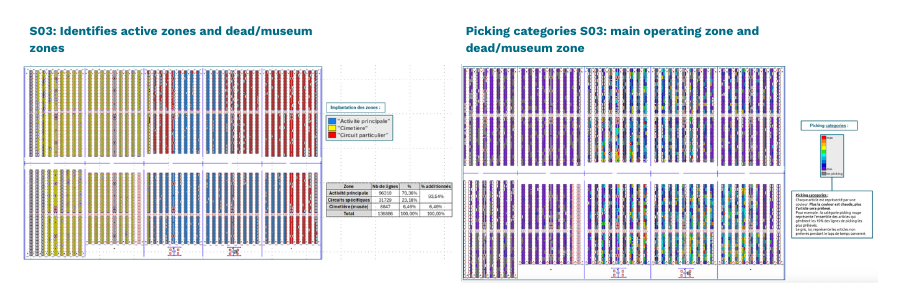

Scenario 3 : Based on scenario 1, adding the creation of :

→ High activity zone centered,

→ Cemetery zone for slow movers, moved to the warehouse periphery.

👉 This Audit allows us to get concrete avenue for improvement, tailored to site’s specific constraints and offer relevant gains in productivity.

Coming soon : discover our client’s testimonial !

Article written by :